close

Choose Your Site

Global

Social Media

Have you ever wondered how industries produce high-purity nitrogen on demand? Nitrogen generators are essential for many applications, from electronics manufacturing to food packaging.

In this post, we’ll explore the two main types of nitrogen generators: PSA Nitrogen Generators and Membrane Nitrogen Generators. Understanding the differences between these technologies is crucial for businesses looking to optimize their nitrogen supply.

You’ll learn how each system works, their benefits, and which is best suited for different industrial needs.

A PSA (Pressure Swing Adsorption) Nitrogen Generator uses a process to separate nitrogen from the air. The technology relies on Carbon Molecular Sieve (CMS), which adsorbs oxygen and other impurities from the air, allowing nitrogen to pass through.

In simple terms, air is passed through two adsorption beds filled with CMS. One bed adsorbs oxygen while the other regenerates. This alternating process ensures a continuous supply of nitrogen.

PSA Nitrogen Generators are highly effective for producing nitrogen with high purity levels. Here’s why they stand out:

Purity: Achieve nitrogen purity from 95% to 99.999%.

Efficiency: Ideal for industries requiring high-purity nitrogen.

Cost-Effectiveness: These systems are cost-efficient over the long run.

Operational Savings: PSA systems help reduce operational costs by eliminating the need for purchased nitrogen.

PSA Nitrogen Generators come with some key features that make them reliable and efficient:

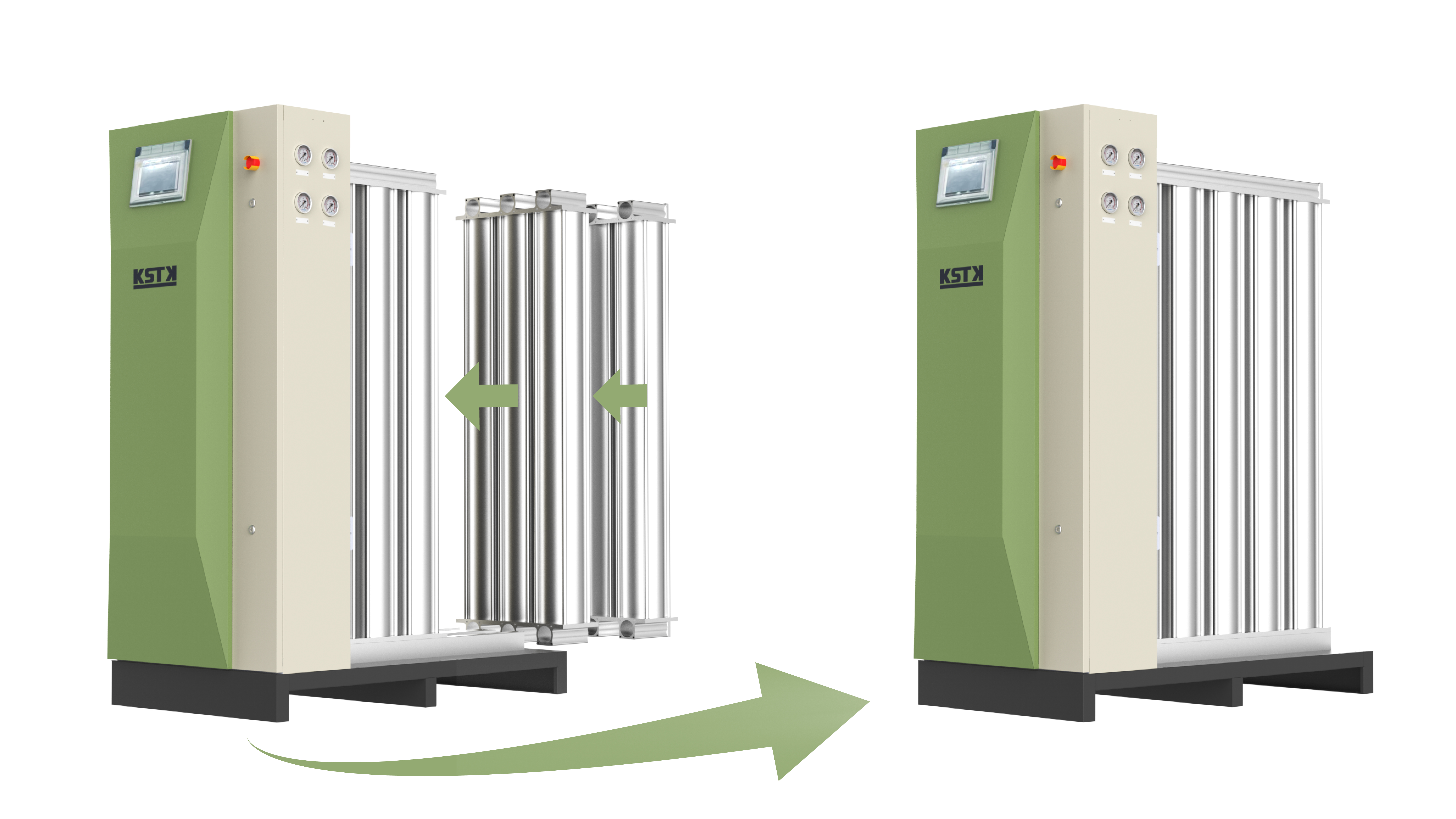

Dual Adsorption Towers: Enables continuous operation by alternating between adsorption and regeneration.

Automatic Switching: The switching process between the two beds is automatic, requiring minimal human intervention.

Low Maintenance: Once installed, these systems require very little maintenance.

Long Lifespan: With proper care, PSA Nitrogen Generators can last for decades.

Industries that need ultra-high-purity nitrogen often rely on PSA systems. Common applications include:

Pharmaceutical Manufacturing: Ensures the highest nitrogen purity for sensitive products.

Electronics Manufacturing: Maintains precision in creating electronic components.

Food Packaging: Helps preserve food by maintaining nitrogen levels during packaging.

Laser Cutting: Provides the necessary high-purity nitrogen for cutting and engraving.

PSA Nitrogen Generators are versatile and essential for businesses that need a reliable source of high-purity nitrogen.

A Membrane Nitrogen Generator uses a selective permeation process to separate nitrogen from compressed air. This technology involves passing air through a hollow-fiber membrane, where smaller molecules, like oxygen and water vapor, pass through the membrane faster than nitrogen. As a result, nitrogen is left behind, ready for use.

The membrane acts as a barrier, allowing nitrogen to exit as the purified gas while rejecting other gases.

Membrane Nitrogen Generators offer several benefits, especially in smaller or mobile operations:

Compact and Lightweight: These systems have a smaller footprint, making them ideal for tight spaces.

Simple Design: Fewer moving parts make these systems easy to maintain.

Quiet Operation: They run quietly, making them suitable for noise-sensitive environments.

Ideal for Mobile Operations: Their lightweight design makes them a great fit for portable applications.

Membrane systems are designed for ease and efficiency:

Low Maintenance: These systems need very little upkeep once installed.

Easy Installation and Operation: Set up and use is simple, making it a great choice for small-scale businesses.

Membrane Nitrogen Generators are often used in industries where nitrogen purity requirements are moderate:

Tire Inflation: Keeps tires inflated with nitrogen for better performance.

Fire Prevention Systems: Ensures nitrogen levels to prevent fire hazards in pipelines.

Oil and Gas Industry: Used for inerting and maintaining safe environments.

Food and Beverage Packaging: Helps preserve food quality by creating an inert atmosphere.

Membrane Nitrogen Generators provide an efficient and reliable nitrogen supply, especially for applications requiring moderate purity.

When it comes to nitrogen purity, PSA Nitrogen Generators have the upper hand.

PSA systems can achieve nitrogen purity levels of up to 99.999%, making them ideal for industries that require ultra-pure nitrogen.

For high-purity needs, PSA is the better choice, especially for applications like pharmaceuticals and electronics manufacturing.

PSA systems are typically larger, featuring dual adsorption towers and additional components like valves and control systems. They require more space for installation.

Membrane systems, on the other hand, are compact and lightweight, making them an excellent choice for operations with limited space or mobile applications.

PSA systems tend to be more cost-efficient for applications requiring high-purity nitrogen, as they provide greater nitrogen yield at higher purities.

For businesses looking to optimize costs while maintaining quality, PSA systems offer long-term savings in high-purity settings, while membrane systems are better for low-cost, smaller-scale operations.

When selecting the right nitrogen generator, it's essential to keep a few key factors in mind:

Nitrogen Purity Requirement: If your business demands high-purity nitrogen, PSA Nitrogen Generators are your best option.

Space Availability: PSA systems tend to be larger, requiring more installation space. Membrane systems are compact and fit in tighter spaces.

Budget Constraints: PSA systems are cost-effective for high-purity application over the long terms.

Desired Maintenance Frequency: PSA systems need regular maintenance, while membrane systems are low-maintenance with fewer components to manage.

Industry-Specific Needs: Different industries have specific nitrogen requirements, making it essential to choose a system that aligns with your business needs.

Desired Maintenance Frequency: PSA systems need regular maintenance, while membrane systems are low-maintenance with fewer components to manage.

Industry-Specific Needs: Different industries have specific nitrogen requirements, making it essential to choose a system that aligns with your business needs.

PSA Nitrogen Generators are ideal for high-purity applications, including:

Pharmaceuticals: Ensures ultra-pure nitrogen for sensitive processes.

Electronics Manufacturing: Provides clean, high-purity nitrogen for precise component production.

Laser Cutting: Delivers the high-purity nitrogen needed for effective cutting and engraving.

If your business requires ultra-pure nitrogen, PSA Nitrogen Generators are the clear winner. PSA systems can provide nitrogen purity levels up to 99.999%, making them ideal for applications like pharmaceuticals, electronics manufacturing, and laser cutting. These industries need high-quality nitrogen to ensure precision, safety, and product integrity.

PSA systems offer a consistent and reliable nitrogen supply, ensuring that businesses can meet stringent purity standards. Their efficiency in producing high-purity nitrogen makes them the best option when quality and precision are a top priority.

PSA and Membrane Nitrogen Generators each has its own benefits. PSA systems provide high-purity nitrogen suitable for demanding industries, while membrane systems are compact and quieter for moderate purity needs.

When choosing the right system, consider your nitrogen purity requirements, available space, and budget.

For personalized recommendations, contact KSTK to find the perfect nitrogen generator tailored to your business needs.

A PSA Nitrogen Generator can last over 20 years with proper maintenance. The Carbon Molecular Sieve (CMS), a crucial component, can last decades if not exposed to contamination. Regular maintenance ensures the longevity and performance of the system.

For optimal performance, PSA Nitrogen Generators should undergo annual maintenance. Key tasks include filter changes, checking CMS, and ensuring the system's overall functionality. Regular checks help avoid costly repairs and downtime.

Membrane Nitrogen Generators typically achieve purity between 95% and 99%. For higher purity, the system becomes less efficient. When ultra-pure nitrogen is required, PSA systems are a better choice due to their higher efficiency at achieving purities up to 99.999%.

Using a PSA system for lower purity needs can be overkill. It’s more costly and energy-intensive than necessary. Membrane systems offer a more affordable and energy-efficient alternative for these applications.