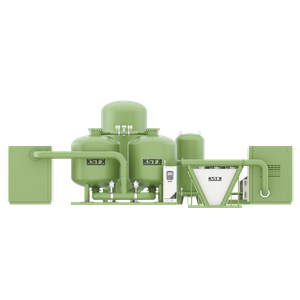

Built-in Air Purification Units

The integrated air dryer and filtration system ensures that only clean, dry air enters the modular oxygen generator. This protects the molecular sieves from moisture and contaminants, prolongs equipment life.

Precision Pressure Regulation

Pressure regulators from AirTAC (Taiwan) ensure stable and accurate outlet pressure, guaranteeing end-user process requirements are consistently met.