close

Choose Your Site

Global

Social Media

The need for reliable, cost-effective, and on-demand oxygen generation has skyrocketed in recent years. Pressure Swing Adsorption (PSA) oxygen generators are fast becoming the preferred solution for a wide range of industries—from healthcare to metallurgy, aquaculture, pharmaceuticals, and more. But why exactly are PSA oxygen plants in such high demand?This article explores the major advantages of using a PSA oxygen generator and answers commonly asked questions to help you make informed decisions for your operations.

A PSA oxygen generator is a type of gas separation system that produces high-purity oxygen from compressed air. It works on the principle of Pressure Swing Adsorption, which utilizes special molecular sieves—usually zeolite—to selectively adsorb nitrogen molecules while allowing oxygen to pass through. The result is oxygen with a purity level typically ranging from 90% to 95%.

This method of oxygen generation is known for its efficiency, reliability, and sustainability. Unlike traditional cryogenic oxygen plants, PSA systems operate at ambient temperatures and require less infrastructure, making them suitable for both large-scale and small-scale installations.

One of the most compelling benefits of PSA oxygen generators is cost efficiency. Traditional oxygen supply methods often involve high transportation and storage costs, particularly when dealing with gas cylinders or liquid oxygen tanks. These recurring costs can significantly affect operational budgets over time.

With a PSA system, oxygen is generated on-site, eliminating the need for third-party suppliers and transportation logistics. The capital expenditure for installing a PSA plant is offset relatively quickly by the reduced operating costs and no need for storage tanks or cylinder refills.

Additionally, energy consumption in PSA systems is considerably lower than in cryogenic processes, making them highly energy-efficient. Most plants are automated and require minimal supervision, further reducing the need for human labor and lowering maintenance costs.

| Comparison Criteria | PSA Oxygen Generator | Traditional Cylinder Supply |

|---|---|---|

| Oxygen Purity | 99.5% | Varies (often 99%) |

| Recurring Costs | Low | High (transport, refills) |

| Initial Investment | Medium | Low |

| Operating Cost | Low | High |

A critical requirement for sectors like healthcare and industrial manufacturing is an uninterrupted oxygen supply. PSA oxygen plants provide 24/7 oxygen generation, as long as compressed air and power are available. This real-time generation capability is particularly advantageous during emergencies or supply chain disruptions.

The system can be customized to meet specific oxygen flow rates and purity requirements, ensuring your operation is never short of vital oxygen. Unlike gas cylinders that need regular replacement, PSA systems offer constant oxygen availability, minimizing downtime and increasing productivity.

Moreover, the integration of control panels and automated alerts ensures real-time monitoring, allowing operators to take immediate action in case of pressure drops or maintenance needs.

As organizations strive to reduce their carbon footprint, PSA oxygen plants offer a sustainable alternative to traditional oxygen delivery methods. By producing oxygen on-site, these systems eliminate the need for transportation, thereby cutting down on fuel consumption and greenhouse gas emissions.

The PSA process is also non-polluting, as it involves no chemical reactions or waste products. The only input required is ambient air, and the only by-product is nitrogen, which is harmless and released back into the atmosphere.

Additionally, because the oxygen is produced as needed, there’s no risk of leakage or wastage associated with stored oxygen cylinders. This not only enhances operational safety but also aligns with global sustainability initiatives.

Traditional oxygen delivery methods, such as high-pressure cylinders and liquid oxygen tanks, pose significant safety risks, including explosion hazards, fire risks, and handling injuries. PSA oxygen plants, on the other hand, operate at much lower pressures, reducing the likelihood of accidents.

Since the oxygen is generated and consumed on-site, there's no need for transport, storage, or cylinder handling, which are common sources of safety incidents. Moreover, PSA systems are typically equipped with safety features like overload protection, automatic shutdown, and oxygen concentration monitoring, further enhancing operational control.

Also noteworthy is the ability to integrate PSA plants with Remote Monitoring Systems, allowing for centralized control and data tracking. This increases process transparency, aids in predictive maintenance, and ensures compliance with industry regulations.

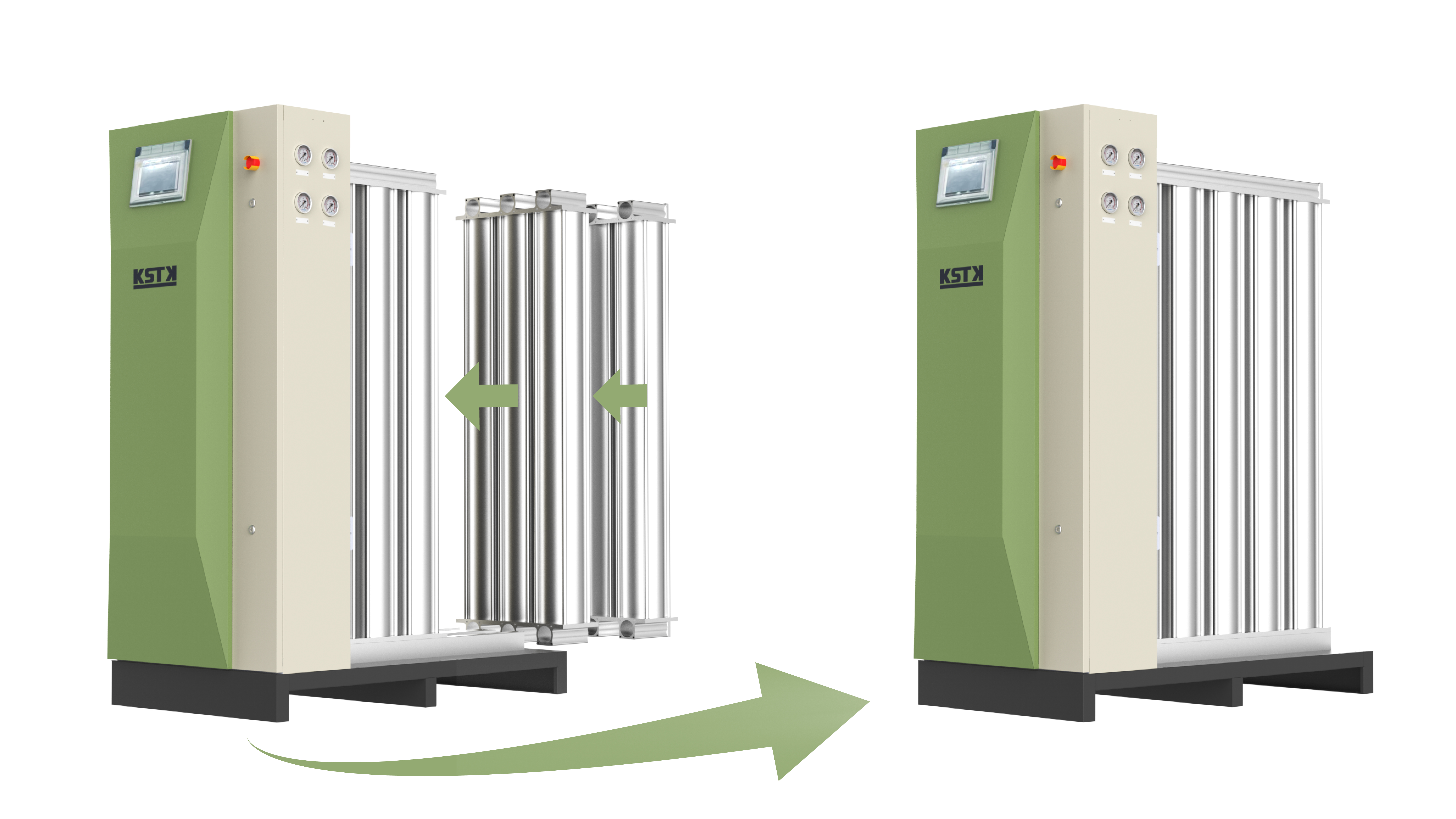

Another strong suit of PSA oxygen plants is their modular and scalable design. Whether you need oxygen for a small veterinary clinic or a large-scale steel plant, PSA systems can be tailored to suit your specific needs. The modular units allow for incremental expansion, meaning you can start small and scale up as demand increases—without overhauling the entire infrastructure.

Their versatility also makes them ideal for a wide range of applications:

Medical Facilities: Reliable oxygen for ICUs, operating rooms, and emergency wards.

Water Treatment Plants: Enhanced aerobic digestion and odor control.

Aquaculture: Improved fish growth and reduced mortality.

Glass and Metal Processing: Higher furnace temperatures and improved combustion.

Pharmaceutical Manufacturing: Controlled environment for sensitive production processes.

The adaptability of PSA systems makes them a smart, long-term investment for businesses in diverse sectors.

A PSA oxygen generator works by adsorbing nitrogen molecules from compressed air using zeolite molecular sieves, allowing the remaining oxygen to be collected and delivered as a product gas. The process alternates between two towers, enabling continuous operation.

PSA systems typically produce oxygen with a purity range of 90–95%, which is suitable for most industrial and medical applications. If 99% high purity oxygen is required, additional oxygen purifier is requested.

Yes. Because PSA plants are designed for continuous and automatic operation, they are highly reliable during critical situations—especially when paired with backup power systems.

With proper maintenance, a PSA oxygen generator can last 10–15 years or more. Routine checks, timely replacement of filters, and occasional service of the compressor unit are essential for maximizing its lifespan.

Absolutely. PSA systems are compact and do not require extensive infrastructure, making them ideal for remote or rural installations with limited access to oxygen delivery networks.

In an era where cost-efficiency, reliability, and sustainability are at the forefront of operational strategy, PSA oxygen generators emerge as a clear winner. From reducing costs and minimizing environmental impact to enhancing safety and ensuring an uninterrupted supply, the advantages are both immediate and long-term.

If you're considering an upgrade or a new installation for your oxygen needs, a PSA oxygen plant offers a smart, scalable, and future-proof solution that adapts to your operational dynamics without compromising on performance.