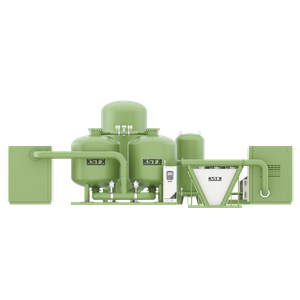

Built-in Dryer & Filters

The integrated air dryer and filtration system ensures that only clean, dry air enters the oxygen generator. This protects the molecular sieves from moisture and contaminants, prolongs equipment life.

Precision Pressure Sensor

High-quality SMC pressure sensors ensure precise pressure monitoring, with real-time data transmission to the PLC for enhanced process control.