close

Choose Your Site

Global

Social Media

PSA nitrogen generators produce high-purity nitrogen on-site by separating gases from compressed air using pressure swing adsorption technology.

The system uses carbon molecular sieves to trap oxygen and moisture, allowing nitrogen to pass through continuously with cycles of adsorption and regeneration.

Nitrogen purity from PSA generators ranges from 90% to 99.999%, meeting the needs of industries like food, pharmaceuticals, electronics, and manufacturing.

On-site nitrogen generation cuts costs by up to 80%, reduces delivery risks, and improves workplace safety by eliminating the need for gas cylinders.

PSA nitrogen generators offer reliable, energy-efficient operation with advanced safety features and remote monitoring for consistent performance.

Compared to membrane and cryogenic systems, PSA generators provide higher purity, better cost savings, and simpler maintenance for most applications.

Industries use PSA nitrogen for packaging, preserving food, manufacturing electronics, and creating safe inert atmospheres in chemical and pharmaceutical processes.

The PSA nitrogen generator market is growing rapidly due to industrial demand, technological advances, and increasing focus on sustainability and environmental benefits.

Pressure swing adsorption, often called PSA, is a technology that separates gases based on how they interact with solid materials under different pressures. In the context of a psa nitrogen generator, this process allows for the efficient extraction of nitrogen from compressed air. PSA works by taking advantage of the fact that different gases have unique adsorption characteristics. When air is pressurized, certain gases, such as oxygen and moisture, stick to the surface of special materials inside the generator, while nitrogen passes through. By cycling the pressure up and down, the system can trap unwanted gases and release pure nitrogen for use.

PSA technology relies on the principle that the adsorption capacity of a material changes with pressure. By switching between high and low pressure, the system can selectively capture and release gases, making it ideal for gas separation tasks like nitrogen generation.

A psa nitrogen generator uses a series of steps to separate nitrogen from other components in compressed air. The process involves two main vessels, each filled with carbon molecular sieves. These sieves act as filters that attract and hold onto oxygen, carbon dioxide, and water vapor, while allowing nitrogen to flow through. The system operates in cycles, alternating between adsorption and regeneration phases to ensure a continuous supply of nitrogen gas.

Here’s a simplified breakdown of the PSA process:

Compressed air enters one of the adsorption towers packed with carbon molecular sieves.

Oxygen and other impurities are adsorbed by the sieves, while nitrogen passes through as purified gas.

The tower continues to adsorb oxygen during this phase, producing nitrogen at the desired purity.

Some of the produced nitrogen flows into the second tower in the opposite direction to purge out the adsorbed oxygen during regeneration.

The pressure in the regenerating tower drops, causing the sieves to release the trapped oxygen and other gases.

The two towers switch roles, allowing for uninterrupted nitrogen generation.

This cycle repeats, providing a steady stream of high-purity nitrogen. The psa nitrogen generator operates at ambient temperature, making it energy-efficient and reliable for many industries.

A nitrogen generator that uses pressure swing adsorption contains several essential parts. Each component plays a specific role in the nitrogen generation process. The following table outlines the main components and their functions:

Component | Role in Nitrogen Production Process |

|---|---|

Carbon Molecular Sieve (CMS) | Selectively adsorbs oxygen, carbon dioxide, and moisture from compressed air, allowing nitrogen to pass through. |

Dual Adsorption Towers/Vessels | Alternate between adsorption and regeneration phases to maintain continuous nitrogen production. |

Air Screw Compressor and Air Tank | Supply and store compressed air before it enters the adsorption towers. |

Control System/Panel | Manage timing and switching of adsorption and regeneration cycles for steady nitrogen flow. |

Nitrogen generators also include valves, sensors, and sometimes advanced control systems to monitor purity and flow rates. These features help maintain the efficiency and safety of the nitrogen gas generators. By using compressed air as the raw material, the generator can produce nitrogen gas on demand, supporting a wide range of industrial applications. The combination of these components ensures that the psa nitrogen generator delivers reliable, high-quality nitrogen with minimal maintenance.

Nitrogen purity describes the percentage of nitrogen present in the gas produced by a PSA system. PSA nitrogen generators can deliver a wide range of purity levels, making them suitable for many applications. Most PSA systems achieve nitrogen purity from 90% up to 99.999%. The process uses pressure swing adsorption to separate nitrogen from oxygen and other gases in compressed air.

The following table shows typical nitrogen purity levels and their common uses:

Nitrogen Purity Level | Typical Applications |

|---|---|

95-97% | Tire inflation, fire suppression, chemical processes |

98-99% | Food packaging, fermentation, metal annealing |

99.9% | Pharmaceutical and chemical manufacturing |

99.99% | Semiconductor manufacturing, laboratory research |

99.999% | Analytical instrumentation, electronic chip manufacturing, sensitive optical equipment |

PSA technology allows users to select the right nitrogen purity for their needs. High purity nitrogen is essential for industries that require strict control over contaminants.

Several operational parameters influence the purity of nitrogen produced by PSA systems. The most important factors include cycle time, temperature, and air quality. Cycle time and temperature affect how gases move and interact inside the adsorber columns. Proper control of these variables ensures optimal nitrogen purity.

The table below lists key operational parameters and their effects on nitrogen purity:

Operational Parameter | Effect on Nitrogen Purity |

|---|---|

Gas Flow Rate | High flow rates reduce adsorption capacity and nitrogen purity. |

Carbon Molecular Sieve Aging | Aging or contamination lowers adsorption capacity, decreasing purity. |

Electromagnetic Valve | Malfunction disrupts gas flow control, impacting purity. |

Regulation Valve | Improper adjustment affects gas flow and outlet pressure, reducing purity. |

Cycle Time | Influences mass transfer and diffusion, affecting purity levels. |

Temperature | Alters mass transfer and diffusion, impacting purity. |

Air Quality | Moisture, oil, and contaminants damage molecular sieve, lowering purity. |

Maintenance | Regular inspection and replacement sustain purity. |

Operators must keep intake air clean and dry to protect the carbon molecular sieve and maintain high purity nitrogen output. They should also monitor pressure, temperature, and dew point sensors to prevent contaminated air from entering the PSA system. Using dryers and filters helps remove oil and moisture, especially when air comes from oil-lubricated compressors. Regular maintenance and precise control of cycle time and temperature support consistent nitrogen purity.

Tip: Operators should always check the air quality and replace molecular sieves as needed to ensure reliable nitrogen gas production.

Industries rely on high purity nitrogen for many critical processes. Pharmaceutical manufacturing uses nitrogen purity between 97% and 99.99% to prevent contamination and maintain drug stability. Nitrogen blanketing in storage tanks and packaging helps retain freshness and protects active ingredients. Food-grade nitrogen, usually between 98% and 99.5% purity, eliminates oxidants, preserves flavor, and prevents spoilage.

Pharmaceutical companies use nitrogen to maintain drug quality and efficacy by displacing oxygen during manufacturing, storage, and packaging.

Food processors use nitrogen to prevent oxidation and microbial growth, extending shelf life and preserving freshness.

Electronics manufacturers require ultra-high purity nitrogen, often 99.999%, to purge moisture and oxygen, preventing oxidation and contamination of sensitive components.

Nitrogen supports processes like soldering in electronics, freeze-drying in pharmaceuticals, and modified atmosphere packaging in food production.

Increasing industrial regulations demand high-quality, contamination-free inert gases to ensure product safety and environmental protection. High-tech sectors such as electronics, pharmaceuticals, and aerospace drive the need for ultra-pure nitrogen to maintain product integrity. Reliable nitrogen supply supports operational efficiency and regulatory compliance across industries.

Note: High purity nitrogen helps industries meet strict standards and improves product quality, safety, and shelf life.

Nitrogen generation in a PSA system relies on two main cycles: adsorption and regeneration. These cycles allow the generator to separate nitrogen from other gases in compressed air and maintain continuous production. The process works best at near ambient temperatures, usually between 20°C and 25°C.

During the adsorption stage, compressed air flows into a bed filled with carbon molecular sieve. Oxygen, moisture, and other gases stick to the surface of the sieve. Nitrogen molecules pass through and collect as the product gas.

In the regeneration stage, the system quickly releases the pressure inside the bed. The trapped gases, such as oxygen and moisture, leave the sieve and vent to the atmosphere. This step prepares the bed for the next cycle of nitrogen production.

These alternating cycles ensure a steady supply of high purity nitrogen. The design supports efficient gas separation and reliable nitrogen generation for many industries.

The carbon molecular sieve (CMS) plays a key role in the nitrogen generation process. Its unique microporous structure allows it to separate gases based on their size and speed. CMS selectively adsorbs smaller oxygen molecules into its pores, while larger nitrogen molecules move past and become the product gas.

CMS has high porosity, which enables fast adsorption and desorption cycles. This feature increases the speed of nitrogen production.

The sieve can achieve nitrogen purity levels up to 99.9999% by efficiently removing oxygen.

CMS improves energy efficiency and reduces operational costs for the generator.

The material remains durable over many cycles, supporting continuous nitrogen generation with low maintenance.

The effectiveness of CMS in gas separation makes it ideal for producing high purity nitrogen gas. Its performance depends on the pore size distribution and the speed at which it adsorbs oxygen.

PSA nitrogen generation systems come in different designs, each affecting efficiency, footprint, and maintenance needs. The traditional dual-tower design uses two adsorption vessels that alternate between adsorption and regeneration. This setup provides reliable nitrogen production but can require more space and higher installation costs.

The KSTK Quad-Tower Nitrogen Generator introduces an advanced approach. This system integrates two sets of adsorption vessels into a single unit, replacing the dual-tower setup. The quad-tower structure simplifies the overall system, reduces the physical footprint, and lowers installation costs. The design also minimizes operational and maintenance complexity.

Key features of the KSTK Quad-Tower system include:

Enhanced operational efficiency and stability through integrated vessel design.

A patented modular valve manifold that improves system efficiency and reduces leakage risks.

Premium pneumatic valves and custom-engineered molecular sieves for longer lifespan and consistent purity.

An automatic venting system that ensures only high purity nitrogen reaches the user.

Advanced PLC controls for easy operation, remote monitoring, and multilingual support.

The quad-tower design supports nitrogen generation with purities from 95% up to 99.9999%. It delivers continuous 24/7 operation and low operating costs. Compared to dual-tower systems, the quad-tower model offers a smaller footprint, easier maintenance, and greater efficiency. This makes it an excellent choice for businesses seeking reliable and economical nitrogen production.

Businesses often seek ways to reduce expenses while maintaining reliable gas supply for their operations. PSA nitrogen generators offer significant cost savings compared to purchasing bottled or bulk nitrogen. Companies can save between 75% and 92% on nitrogen costs by switching to on-site nitrogen generation. The price of bottled nitrogen includes not only the base cost but also delivery fees, cylinder rentals, evaporative losses, labor for handling, and extra insurance. These hidden costs add up quickly.

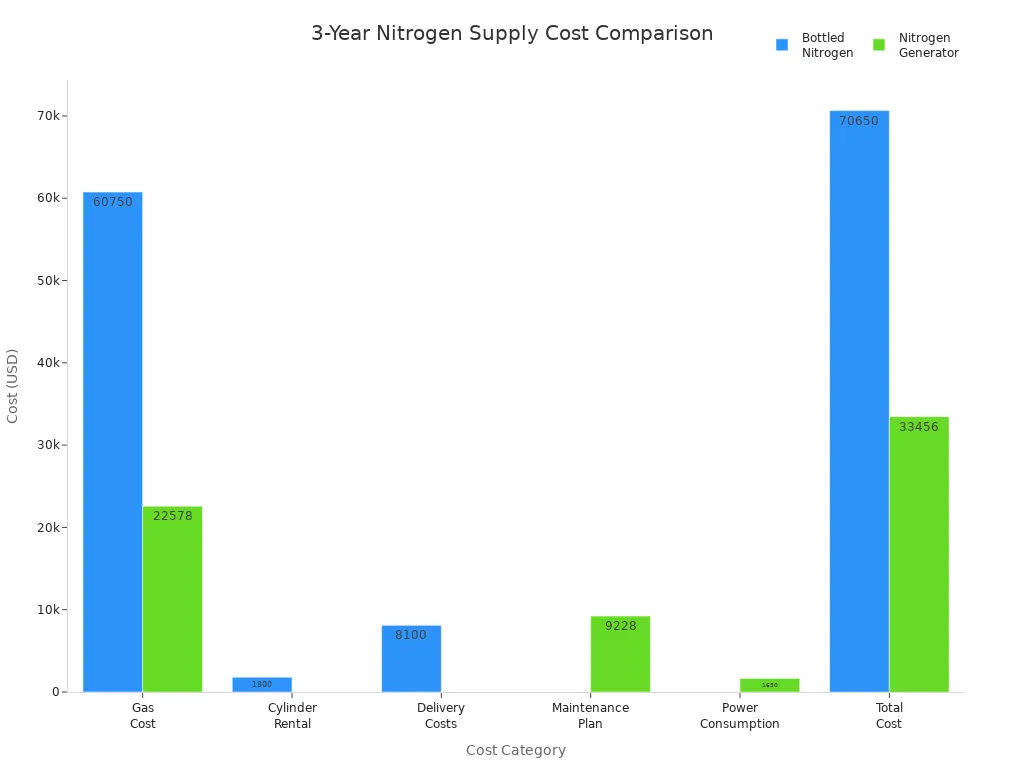

Many facilities recover the initial investment in a PSA nitrogen generator in less than two years. Over time, users can save up to 80% on nitrogen costs, making PSA systems a smart financial choice. The following table shows a cost comparison over three years for one LC-MS instrument:

Cost Category | Bottled Nitrogen (3 years) | Nitrogen Generator (3 years) |

|---|---|---|

Gas Cost | $60,750 | $22,578 |

Cylinder Rental | $1,800 | N/A |

Delivery Costs | $8,100 | N/A |

Maintenance Plan | N/A | $9,228 |

Power Consumption | N/A | $1,650 |

Total Cost | $70,650 | $33,456 |

This chart highlights a 51% cost saving over three years when using a nitrogen generator. Facilities benefit from low operating costs and a short payback period, making PSA technology a practical solution for long-term savings.

On-site nitrogen generation transforms how companies manage their gas supply. Facilities no longer need to transport or store nitrogen cylinders and tanks, which reduces logistical complexity and costs. Producing nitrogen at the facility ensures a continuous and reliable supply, minimizing downtime caused by delivery delays or inventory shortages.

On-site nitrogen generation eliminates the need for managing deliveries, inventory tracking, and cylinder returns.

Continuous production prevents stoppages related to cylinder changes or late deliveries.

Handling and storage of high-pressure cylinders or bulk tanks are no longer necessary, improving workplace safety.

PSA systems are compact, freeing up valuable space and increasing operational flexibility.

Environmental benefits include reduced transportation emissions, supporting greener operations.

On-site nitrogen generation allows businesses to tailor output to their specific needs. The ability to produce nitrogen on demand supports uninterrupted production and enhances overall efficiency.

PSA nitrogen generators incorporate advanced safety features to ensure dependable operation. Electrical protections, such as IP54-rated control cabinets and grounding systems, prevent accidental contact and electrical hazards. Smart safety devices, including leakage protectors and dual motor protection, respond quickly to faults.

Multi-layered safety systems monitor pressure, temperature, and oxygen content. These systems trigger automatic shutdowns and remote alarms if abnormalities occur. Modular quick-assembly designs use safety pin locking mechanisms to prevent detachment. Remote monitoring platforms allow operators to view real-time status, perform diagnostics, and respond rapidly to failures.

Self-diagnosis systems embedded in PLCs provide error codes for quick fault identification. Strict power management and access control prevent misoperation, while optimized piping structures and regular leak detection reduce the risk of high-pressure gas leaks. Fire hazard prevention measures address oxygen-rich emissions and ensure safe exhaust and ventilation.

PSA nitrogen generators meet industry safety standards and include built-in alarms, redundancy, and fail-safe designs. Regular inspections and professional servicing further enhance reliability and safety.

PSA nitrogen generators play a key role in promoting sustainability across industries. These systems produce nitrogen directly from ambient air, which helps companies reduce their reliance on traditional supply chains. Conventional nitrogen supply often involves energy-intensive processes such as liquefaction, chilling, bottling, and transportation. Each step consumes large amounts of electricity and releases greenhouse gases into the atmosphere. By generating nitrogen on-site, PSA technology eliminates these steps and lowers the overall carbon footprint.

Many industries seek ways to minimize their impact on the environment. PSA nitrogen generators support this goal by using adsorption to separate nitrogen from air, rather than relying on the Haber-Bosch process. The Haber-Bosch method, commonly used in large ammonia plants, burns fossil fuels and contributes heavily to global carbon emissions. PSA systems avoid this carbon-intensive route, offering a cleaner alternative for nitrogen production.

Advances in renewable energy have further improved the sustainability of PSA nitrogen generators. Facilities can now power these systems with solar panels or wind turbines, reducing their dependence on fossil fuels. This shift helps companies meet environmental targets and supports climate change mitigation efforts. As a result, businesses using PSA technology often report lower carbon footprints in their product life cycle analyses.

PSA nitrogen generators help companies align with global sustainability goals and regulatory expectations. They offer a practical solution for reducing greenhouse gas emissions and supporting environmental responsibility.

Manufacturers have responded to growing environmental concerns by designing energy-efficient PSA nitrogen generators. Many models now use RoHS-compliant materials and eco-friendly packaging to minimize electronic waste. Companies also focus on reducing the energy consumption of their systems, which benefits both the environment and operational costs.

The use of PSA nitrogen generators extends the lifespan of materials in industrial settings. Nitrogen prevents oxidation and corrosion, which reduces waste and the need for frequent replacements. This indirect benefit supports sustainability by lowering resource consumption and promoting longer-lasting equipment.

The importance of Environmental, Social, and Governance (ESG) criteria continues to shape the market for PSA nitrogen generators. Businesses must integrate sustainability into their operations and product development to meet regulatory standards and customer expectations. PSA technology provides a reliable way to achieve these goals while maintaining efficient production.

Nitrogen generators use different technologies to separate nitrogen from air. PSA and membrane systems are the most common types. Each method has unique strengths and limitations. The table below highlights the main differences between PSA and membrane nitrogen generators:

Aspect | PSA Nitrogen Generators | Membrane Nitrogen Generators |

|---|---|---|

Nitrogen Purity | 95% to 99.9995% | 95% to 99.9% |

Suitable Purity Range | High purity applications (over 98%) | Lower purity applications |

Energy Consumption | Higher, due to adsorption/desorption cycles | Lower, membrane separation uses less compressed air |

Efficiency at High Purity | Efficient and cost-effective for >98% purity | Efficiency drops and costs rise above 98% purity |

Size and Mobility | Larger, heavier, less mobile | Compact, lighter, mobile |

Maintenance | More moving parts, higher maintenance | Fewer moving parts, less maintenance |

Service Life | Longer service life | Membranes wear out over time |

PSA nitrogen generators deliver higher purity and work well for industries that need consistent, high-quality nitrogen. Membrane systems suit smaller operations or those with moderate purity needs. Membrane nitrogen generators are easier to move and maintain, but they cannot reach the ultra-high purity levels of PSA systems.

Cryogenic nitrogen generators use fractional distillation to produce ultra-high purity nitrogen. This process chills air to extremely low temperatures, separating gases based on their boiling points. PSA nitrogen generators achieve high purity with simpler technology and lower energy use.

Nitrogen generators can save more than 50% on operating costs compared to cryogenic supply.

On-site PSA nitrogen generation removes the need for transporting heavy nitrogen containers, reducing environmental impact.

The return on investment for a PSA nitrogen generator usually ranges from 6 to 18 months, depending on demand.

Operating costs for PSA nitrogen generators are much lower than those for nitrogen cylinders, liquid nitrogen dewars, or bulk liquid nitrogen.

Cryogenic systems are best for facilities with extremely high nitrogen consumption, but they involve complex equipment and higher expenses.

A business using bulk cryogenic nitrogen may spend over $27,000 each year, including rental and delivery fees. In contrast, a PSA nitrogen generator producing similar amounts costs about $2,700 annually for maintenance and operation. After the initial payback period, the business saves around $25,000 per year.

PSA nitrogen generators offer a simpler, more cost-effective solution for most applications. Cryogenic systems remain necessary only for the highest purity and volume needs.

Selecting the best nitrogen generator depends on several factors. Companies should consider purity requirements, volume, maintenance, and sustainability goals.

PSA and membrane nitrogen generators help reduce greenhouse gas emissions by avoiding liquefaction and transportation.

Cryogenic nitrogen generation uses large amounts of energy and produces more emissions.

On-site generation with PSA or membrane systems avoids transportation risks and costs.

PSA and membrane nitrogen generators are safer to operate, since they do not involve extremely cold liquids.

Both PSA and membrane systems support sustainability and lower the carbon footprint of industrial processes.

PSA nitrogen generators provide higher purity and long-lasting performance, making them ideal for demanding applications. Membrane nitrogen generators suit businesses that need moderate purity, compact size, and easy maintenance. Cryogenic systems fit only the largest operations with strict purity and volume needs.

Tip: Companies should match their nitrogen generator choice to their specific purity, volume, and operational requirements. On-site PSA and membrane systems offer safety, cost savings, and environmental benefits for most industries.

Industries rely on PSA nitrogen generators for many essential tasks. These systems provide a steady supply of nitrogen for processes that require an inert atmosphere. Factories use nitrogen to prevent oxidation during chemical reactions and to protect sensitive materials. The automotive and aerospace sectors use nitrogen for tire inflation and fuel tank inerting, which improves safety and reduces risks. Oil and gas companies depend on nitrogen for pipeline purging and leak testing. Nitrogen’s inertness helps prevent accidents and ensures smooth operations.

The following table shows common uses and specific requirements for PSA nitrogen generators in different industries:

Industry | Common Uses of PSA Nitrogen Generators | Specific Requirements / Benefits |

|---|---|---|

Food and Beverage | Packaging and preservation using Modified Atmosphere Packaging (MAP) | High purity nitrogen to prevent oxidation and extend shelf life |

Pharmaceutical and Chemical | Creating inert atmospheres to prevent oxidation in chemicals and meds | Nitrogen used to flush packages, ensuring product stability |

Electronics and Semiconductors | Soldering and component assembly to prevent oxidation | Nitrogen replaces oxygen to ensure high-quality solder joints |

Automotive and Aerospace | Tire inflation and fuel tank inerting | Nitrogen prevents tire deflation and reduces combustion risk |

Oil and Gas | Pipeline inerting, purging oxygen, and leak testing | Nitrogen’s inertness improves safety and prevents accidents |

The KSTK Quad-Tower Nitrogen Generator suits a wide range of industries. Its adjustable output and high purity levels make it ideal for both small businesses and large-scale operations.

Laboratories and medical facilities need nitrogen with very high purity. PSA nitrogen generators produce nitrogen gas up to 99.999% purity, which is critical for pharmaceutical production and sensitive laboratory experiments. These systems use carbon molecular sieves to separate nitrogen from compressed air, ensuring a reliable supply of pure gas. On-site nitrogen generation eliminates the hazards of handling high-pressure cylinders or cryogenic liquids. This improves safety and reduces risks for staff.

Nitrogen generators in medical and laboratory settings offer cost-effectiveness and flexibility. They produce nitrogen only when needed, saving energy and reducing waste. Regular maintenance, such as replacing air filters and monitoring system parameters, keeps the generator working efficiently. These features support strict purity standards and help maintain a safe environment for research and healthcare.

PSA nitrogen generators play a key role in food and beverage packaging and preservation. They separate nitrogen from compressed air using carbon molecular sieves, removing oxygen and other gases that cause spoilage. Nitrogen replaces oxygen in Modified Atmosphere Packaging (MAP), which extends shelf life and keeps food fresh. This process preserves flavor, color, and texture in products like coffee, nuts, fish, and ready-to-eat meals.

Nitrogen slows oxidation and microbial growth, reducing food waste.

On-site nitrogen generation lowers costs by removing the need for cylinder deliveries.

Continuous supply supports packaging, storage, and beverage production.

Nitrogen creates cushioning in snack packaging, protecting products during transport.

Using nitrogen reduces the need for chemical preservatives, offering a safe alternative.

Food processors benefit from reliable, high-purity nitrogen. The KSTK Quad-Tower Nitrogen Generator provides adjustable output and stable purity, meeting the needs of various food and beverage applications.

Electronics and manufacturing industries depend on high-purity nitrogen for many critical processes. Nitrogen creates an inert environment that prevents oxidation, moisture damage, and contamination during production. This is especially important for making semiconductors, circuit boards, lithium batteries, and precision metal parts. Even a small amount of oxygen or moisture can cause defects, lower product quality, or lead to equipment failure.

The KSTK Quad-Tower Nitrogen Generator offers several features that help electronics and manufacturing companies achieve their goals. The table below shows how these features benefit these industries:

Feature | Benefit to Electronics and Manufacturing Industries |

|---|---|

Adjustable Output | Enables tailoring nitrogen supply to specific process needs, improving efficiency and reducing waste. |

Ultra-High Purity (99.999%+) | Ensures critical purity for sensitive manufacturing processes, preventing impurities that could affect product quality and reliability. |

Continuous 24/7 Operation | Provides stable and consistent nitrogen supply, enhancing operational stability. |

Reliable Valves & Premium Absorbents | Deliver long-lasting, efficient performance with minimal maintenance, supporting stable nitrogen quality. |

Patented Valve Manifold Design | Minimizes leakage and simplifies maintenance, ensuring optimal system efficiency. |

Advanced PLC Control System | Allows remote monitoring and control, improving management and operational convenience. |

On-site Generation | Reduces dependency on bottled/liquid nitrogen, lowering costs and simplifying logistics. |

Economic Benefits | Lowers operating costs through elimination of transport/storage fees and offers short payback period. |

Many electronics manufacturers require nitrogen with purity levels above 99.999%. The KSTK Quad-Tower system can deliver this level of purity, which helps prevent oxidation during soldering, assembly, and packaging. Adjustable output means companies can match nitrogen flow to their exact needs, saving energy and reducing waste.

Real-world examples show how PSA nitrogen generators improve manufacturing outcomes. For instance, an electronics manufacturer in the Middle East faced high temperatures and humidity, which threatened nitrogen purity and system stability. By using a PSA nitrogen generator with strong environmental adaptability, the company maintained stable nitrogen purity at 99.5% and reduced downtime. In a lithium battery factory, a four-tower PSA system kept oxygen levels below 10 ppm, which increased product yield by 9% and improved safety.

Industry/Application | Challenge/Pain Point | Solution Provided | Outcome/Effectiveness |

|---|---|---|---|

Electronics Manufacturing (Middle East) | High temperature (45℃) and humidity (80%) affecting stability | PSA nitrogen generator with strong adaptability | Maintained stable nitrogen purity at 99.5%, reduced downtime and failures |

Lithium Battery Factory | Oxygen content must be <10ppm to prevent instability/fire | Four-tower PSA system with deep drying modules | Oxygen stabilized at 5ppm, product yield increased by 9%, improved safety and efficiency |

High-purity, on-site nitrogen generation supports quality, safety, and cost savings in electronics and manufacturing. The KSTK Quad-Tower Nitrogen Generator provides a reliable solution for both small workshops and large-scale factories, helping them meet strict industry standards and production targets.

PSA nitrogen generators have seen many improvements in recent years. Engineers have developed advanced adsorbent materials that hold more gas and work well at lower pressures. These materials help reduce energy use and make systems more reliable. Manufacturers now use rapid pressure swing cycles to optimize how quickly the system switches between adsorption and regeneration. This change boosts energy efficiency.

Many companies design modular PSA units. These units allow users to scale systems up or down based on their needs. Real-time monitoring and control systems now track nitrogen purity and flow. These systems alert operators to problems and help reduce downtime. New adsorbent materials last longer and resist damage from repeated use. This durability extends the life of the generator.

Modern PSA generators include fail-safes and backup components. These features keep the system running even if one part fails. Proper selection of air compressors, especially those with variable speed drives, matches nitrogen demand and saves energy. High-quality filtration protects adsorbent materials from damage. Air drying and temperature control help maintain nitrogen purity. Oil-free rotary screw compressors support continuous operation. Regular maintenance and good system design prevent failures and keep generators working smoothly.

The market for PSA nitrogen generators continues to expand. Many industries need reliable, high-purity nitrogen. Verified Market Reports show that the PSA nitrogen generator segment will grow at a compound annual growth rate (CAGR) of 9.1% from 2026 to 2033. The market revenue is expected to rise from USD 1.2 billion in 2024 to USD 2.5 billion in 2033.

The table below summarizes market growth projections:

Source | Market Segment | CAGR (%) | Time Period | Market Revenue Projection |

|---|---|---|---|---|

Verified Market Reports | PSA Nitrogen Generators | 9.1% | 2026 to 2033 | USD 1.2B (2024) to USD 2.5B (2033) |

U.S. Department of Energy | Nitrogen Production | ~4.0% annual | Next 5 years | Growth driven by technology and industrialization |

Maximize Market Research | Nitrogen Generator Market | 4.1% | 2024 to 2030 | Includes PSA, membrane, cryogenic types |

Industrialization and new technology drive this growth. More companies choose PSA systems for cost savings and reliability. The demand for nitrogen in food, electronics, and pharmaceuticals increases every year.

PSA nitrogen generators help industries lower their environmental footprint. These systems use air as a raw material, which means companies do not need to transport heavy nitrogen cylinders or tanks. On-site generation reduces emissions from delivery trucks and storage facilities.

Energy-efficient PSA designs use less electricity. Advanced adsorbent materials and smart controls help minimize waste. Oil-free compressors and high-quality filtration prevent pollution and protect the environment. Many facilities now power PSA generators with renewable energy sources, such as solar or wind.

PSA nitrogen generators support sustainability goals. They help companies meet environmental standards and reduce greenhouse gas emissions. As technology improves, PSA systems become even more eco-friendly and efficient.

PSA nitrogen generators deliver high-purity nitrogen for industries that demand reliability and safety. Key advantages include:

Consistent output up to 99.999% purity for electronics, food, and pharmaceuticals

On-site production reduces costs, delivery risks, and storage needs

Enhanced workplace safety by removing liquid nitrogen handling

Businesses should:

Assess their purity requirements based on application sensitivity and cost.

Consult experts or explore advanced solutions like the KSTK Quad-Tower Nitrogen Generator.

For further guidance, industry reports and expert consultations offer valuable insights on system selection and implementation.

A PSA nitrogen generator provides on-site nitrogen production. This system reduces costs and ensures a steady supply. Many industries choose PSA technology for its reliability and ability to deliver high-purity nitrogen.

Most PSA nitrogen generators require basic maintenance every 6 to 12 months. Operators should check filters, valves, and molecular sieves. Regular maintenance helps keep the system efficient and extends its lifespan.

Yes, many PSA nitrogen generators allow users to set the desired purity level. Operators can adjust settings to match specific application needs. Some advanced models, like the KSTK Quad-Tower, offer a wide purity range.

PSA nitrogen is safe for food and beverage applications. The system removes contaminants and delivers high-purity nitrogen. Many food processors use PSA nitrogen for packaging, storage, and preservation.

Industries such as food and beverage, electronics, pharmaceuticals, and manufacturing use PSA nitrogen generators. These systems support processes that need high-purity, reliable nitrogen.

The KSTK Quad-Tower design uses four adsorption vessels in one unit. This structure reduces the system’s footprint and installation costs. It also increases operational efficiency and simplifies maintenance.

Tip: Regularly monitor system performance to maintain high nitrogen purity and reliability.